.jpg)

|

Ningbo Jingda Hardware Manufacture Co., Ltd.

|

automobIdler Shaft between a driver shaft and a driven shaft

| Price: | 1.0~2.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

shaft carrying one or more gearwheels that idles between a driver shaft and a driven shaft, usually to reverse the direction of rotation

Product: automobile Idler Shaft

it is a precision engineered component,carrying one or more gearwheels that idles between a driver

shaft and a driven shaft, usually to reverse the direction of rotation

Material: alloy steel 4140

Process: CNC turning and grinding

Heat treatment:with or without according to customer's requirements

could be carburizing and quenching or induce heattreatment in special areas such as

positions for bearing mounted.

Application:carrying one or more gearwheels that idles between a driver shaft and a driven shaft,

usually to reverse the direction of rotation or provide different spacing of gearwheels, esp. in

a gearbox.

Tolerance: depends on drawing requirements.

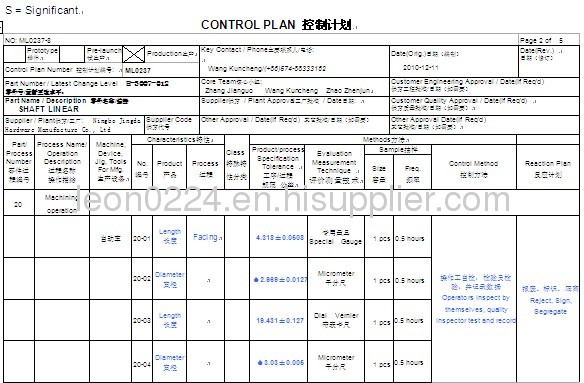

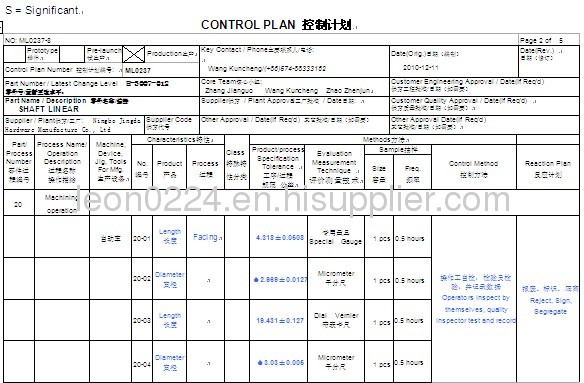

Quality control flow: material in, inspection,lable and record;

mateiral storage and distribution, lable and record;

process and supervise according to Control Plan at operation spot;

randem quality inspection by QC

quality inspection in quality department before putting in warehouse

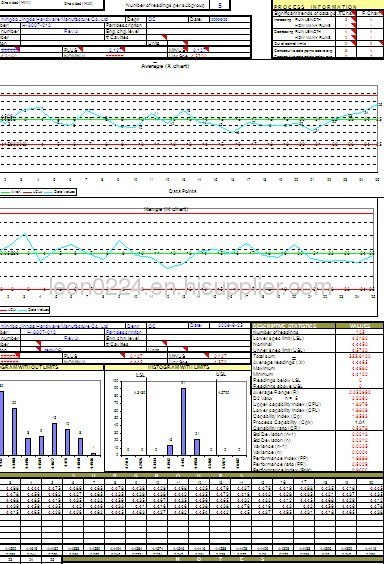

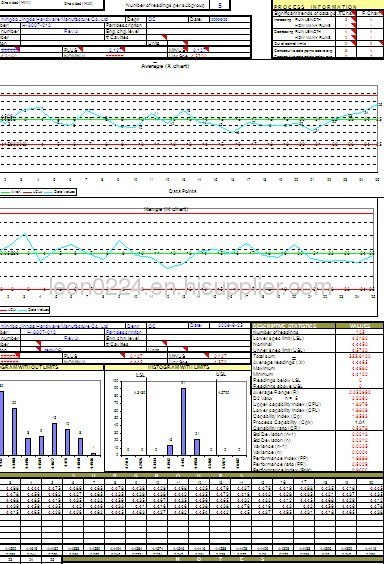

if CPK analyse required,

Packing: automobile Idler Shaft/carton/wood pallet

Lead time: 20days for initial samples or prototype

30-40days for first regular purchasing order

20days from the second orders

it is a precision engineered component,carrying one or more gearwheels that idles between a driver

shaft and a driven shaft, usually to reverse the direction of rotation

Material: alloy steel 4140

Process: CNC turning and grinding

Heat treatment:with or without according to customer's requirements

could be carburizing and quenching or induce heattreatment in special areas such as

positions for bearing mounted.

Application:carrying one or more gearwheels that idles between a driver shaft and a driven shaft,

usually to reverse the direction of rotation or provide different spacing of gearwheels, esp. in

a gearbox.

Tolerance: depends on drawing requirements.

Quality control flow: material in, inspection,lable and record;

mateiral storage and distribution, lable and record;

process and supervise according to Control Plan at operation spot;

randem quality inspection by QC

quality inspection in quality department before putting in warehouse

if CPK analyse required,

Packing: automobile Idler Shaft/carton/wood pallet

Lead time: 20days for initial samples or prototype

30-40days for first regular purchasing order

20days from the second orders

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!