.jpg)

|

Ningbo Jingda Hardware Manufacture Co., Ltd.

|

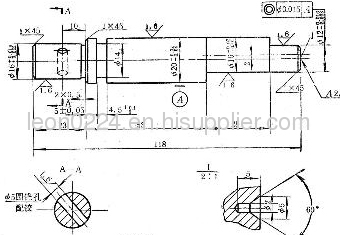

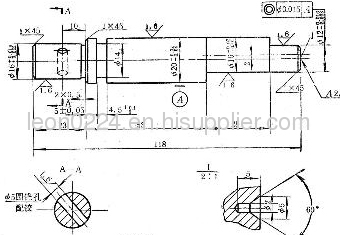

Rotary Engine adjustable Eccentric Shaft

| Price: | 1.0~5.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

eccentric shaft which is off-center,used in transferring rotating power,either it isn't round, or it's not mounted at the center of wherever it is

Product: adjustable eccentric shaft

it is a precision engineered component,eccentric means off-center. Either the shaft isn't round, or

it's not mounted at the center of wherever it it.

- Shaft manufactured from high quality case hardening material for reliability

- more bearing surface area than a standard shaft

- reduce bearing failure & fatigue on high boost engines

- Helps eliminate eccentric shaft flex at high RPM

- Allows rotor clearances to be set to a minimum and seal clearances to be set tighter for

increased horsepower

Material: 42CrMo,SAE1040,1045, 4140, or others as per customer's design

Process: CNC turning, grinding,CNC milling

Heat treatment: with or without according to customer's requirements

could be carburizing and quenching or induce heattreatment in special areas such as

positions for bearing mounted.

Application: they are widely used in transferring rotating power,Tolerance: depends on drawing requirements, the highest tolerance we're doing is 0.005mm.

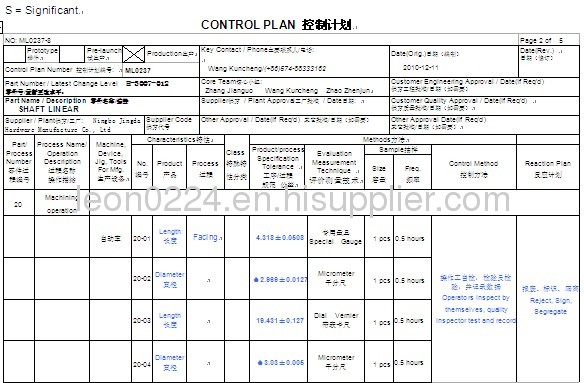

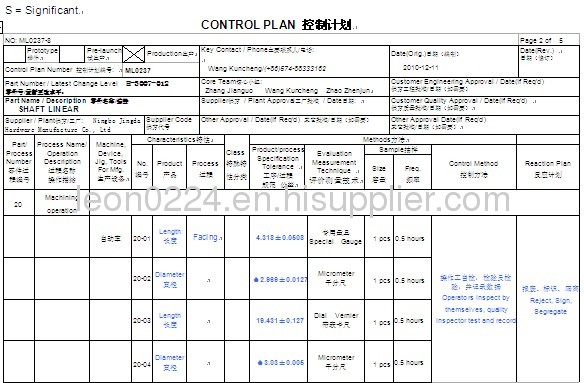

Quality control flow: material in, inspection,lable and record;

mateiral storage and distribution, lable and record;

process and supervise according to Control Plan at operation spot;

randem quality inspection by QC

quality inspection in quality department before putting in warehouse

Packing: adjustable eccentric shaft/carton/wood pallet

Lead time: 20days for initial samples or prototype

30-40days for first regular purchasing order

20days from the second orders

it is a precision engineered component,eccentric means off-center. Either the shaft isn't round, or

it's not mounted at the center of wherever it it.

- Shaft manufactured from high quality case hardening material for reliability

- more bearing surface area than a standard shaft

- reduce bearing failure & fatigue on high boost engines

- Helps eliminate eccentric shaft flex at high RPM

- Allows rotor clearances to be set to a minimum and seal clearances to be set tighter for

increased horsepower

Material: 42CrMo,SAE1040,1045, 4140, or others as per customer's design

Process: CNC turning, grinding,CNC milling

Heat treatment: with or without according to customer's requirements

could be carburizing and quenching or induce heattreatment in special areas such as

positions for bearing mounted.

Application: they are widely used in transferring rotating power,Tolerance: depends on drawing requirements, the highest tolerance we're doing is 0.005mm.

Quality control flow: material in, inspection,lable and record;

mateiral storage and distribution, lable and record;

process and supervise according to Control Plan at operation spot;

randem quality inspection by QC

quality inspection in quality department before putting in warehouse

Packing: adjustable eccentric shaft/carton/wood pallet

Lead time: 20days for initial samples or prototype

30-40days for first regular purchasing order

20days from the second orders

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Eccentric Shaft

Rotary Shaft

Rotary Shaft Seal

Rotary Shaft Oil Seal

Engine Crank Shaft

Eccentric Reducer

More>>